National Telecom Operator Reduces Deployment Time And Cost

Case Study

Background

The challenge

Previously, components were delivered to site and then the power wiring was laid in by experienced wiremen prior to equipment installation. The time this took varied considerably from site to site depending on staff skill levels and availability, which created bottlenecks.

Our approach

Working closely with the client’s subject matter experts, a very detailed Statement of Requirements was defined with all applicable regulations and in-house standards detailed. Building to that standard in a factory environment using repeatable processes and machine cut wiring lengths created a productionised low-cost outcome identical to the Gold Build.

Rainford Solutions has completed almost 4,000 customer projects to date, which gives us a huge library of building blocks from previous designs and experience to draw upon. It means that unique solutions do not begin from a completely blank piece of paper, so development costs, and crucially time to market, are not inhibitors to a highly tailored product.

Our solution

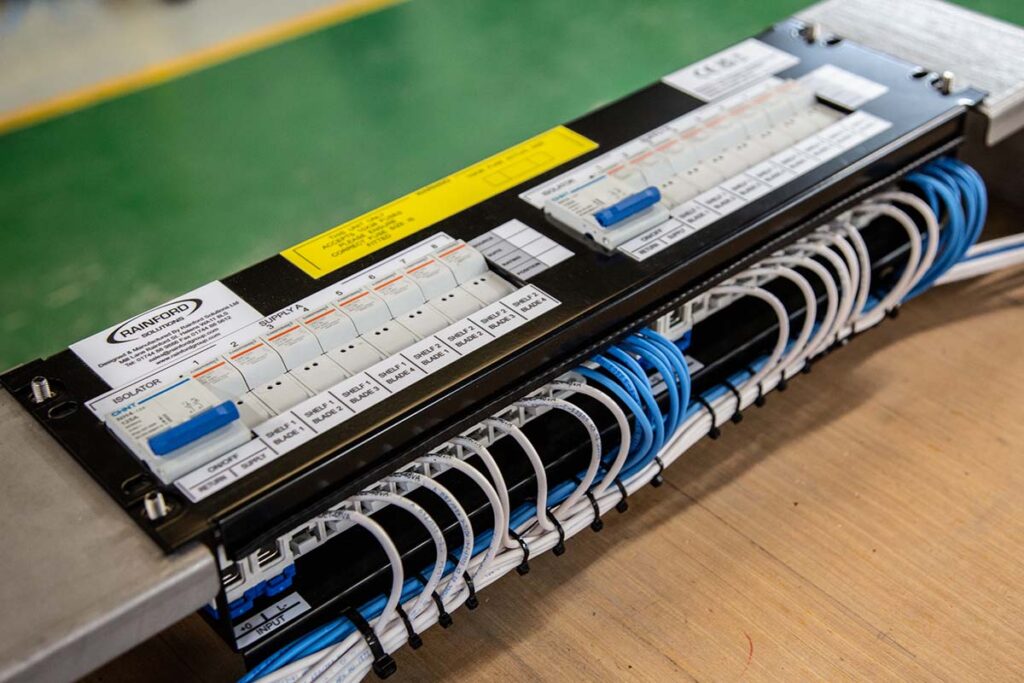

The final racks now include AC and DC wiring pre-installed and labelled which are then delivered to tile location in the exchange (central office) and just need to be connected to site power and fibre.

Outcome

The new approach reduces time on site, errors, project management overheads and multiple visits, leading to a step change in efficiency and total cost as well as enabling a much more rapid rollout for the operator to achieve the service upgrade.