Data centres play a critical role in storing and processing vast amounts of information for businesses, organisations and individuals. As the demand for computing power and storage continues to rise, so does the need for energy-efficient and cost-effective solutions to manage these data centres. Accepted market figures show an average of 30% reduction on cooling power for both hot and cold contained aisles.

As data centres face increasing regulation to reduce their consumption of energy and water, it’s no surprise that the implementation of hot and cold aisle containment has gained popularity in recent years. Not only does this innovative approach improve energy efficiency, but it also enhances a data centre’s overall performance and reliability.

What is hot and cold aisle containment?

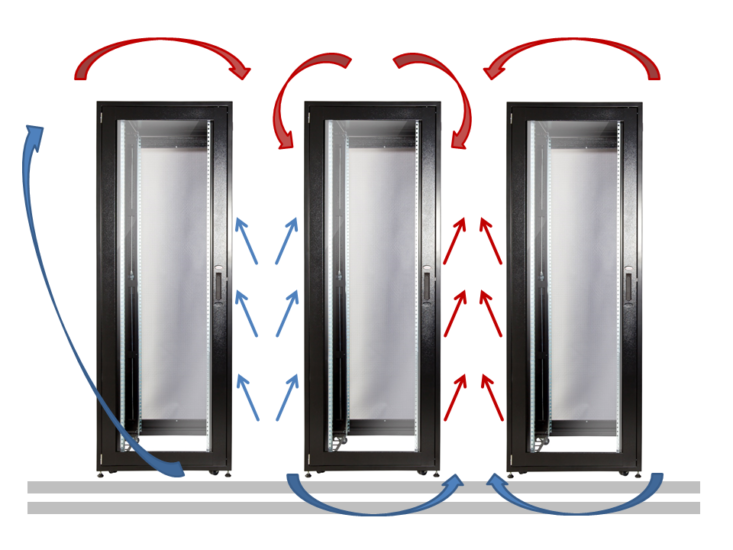

Hot and cold aisle containment is an intelligent data centre airflow management technique used to control the airflow within a data centre by separating hot and cold air streams. In a traditional data centre layout, servers and IT equipment are arranged in rows with alternating aisles. In a hot aisle containment setup, the rear sides of the server racks, which expel hot air, are enclosed to create a separate hot aisle. On the other hand, the front sides of the racks, which intake cooler air, form the cold aisle.

Benefits of hot aisle containment solutions

Energy efficiency: By isolating the hot air and preventing it from mixing with the cold air, hot aisle containment allows for more precise temperature control. This results in a reduced workload for cooling systems, which can then operate more efficiently. This energy saving translates to lower operational costs and a smaller carbon footprint.

Improved cooling effectiveness: The cooling units can deliver cold air directly to the front of server racks, where it’s needed most. This targeted cooling improves the temperature distribution within the racks and prevents hot spots from forming, leading to a more uniform and controlled environment for IT equipment.

Benefits of cold aisle containment solutions

Efficient and precise cooling: In a cold aisle containment setup, the cold air is isolated and directed specifically towards the server inlets. This targeted cooling reduces the chances of hot spots and helps prevent temperature imbalances that can lead to equipment malfunction, significantly reducing hardware failures and downtime.

Flexibility in cooling solutions: Cold aisle containment provides flexibility in choosing the most suitable cooling solutions for the data centre. This could include technologies such as precision air conditioning or liquid cooling.

Scalability: Implementing cold aisle containment facilitates the addition of new equipment without disrupting the existing airflow dynamics. This scalability is vital in data centres that are continuously expanding to accommodate increasing workloads.

As the demand for data processing continues to rise, hot and cold aisle containment stands out as a vital strategy in the pursuit of a sustainable and high-performing data centre environment.

Choosing the right strategy

The importance of hot and cold aisle containment in data centres cannot be overstated. These techniques improve the way data centres operate by enhancing energy efficiency, improving equipment reliability, and facilitating flexible scalability.

The choice between hot aisle and cold aisle containment depends on numerous factors, including the data centre’s layout, existing infrastructure, cooling requirements, and growth projections. Often, a hybrid approach that combines elements of both strategies is employed to achieve optimal results and maximising efficiency and sustainability.

Ultimately, the path to an efficient and high-performing data centre lies in understanding the nuances of these strategies and tailoring them to suit the demands of the ever-evolving digital landscape.

At Rainford, we take a consultative approach to every project. Our aim is to understand what our client needs, then design the best possible solution using the optimum selection of standard and bespoke components. And because we manufacture in the UK, we can ensure tight control over every project from end to end.

Get in touch with our experts if you have a data centre project.